Well 2017 did not go exactly as planned - an unexpected building project took priority over work on the Land Rover when the builder that was extending my daughters house decided that he had over committed himself and simply walked off site leaving my daughter with a "just started" house extension. Getting the extension completed knocking through into the house took up most of my weekends over the summer and while not working that I had an already started building project of my own to get completed.

With the end of the year imminent, the building tools have been put away and work has just restarted on the Land Rover in earnest

Although no real work has been undertaken since June, some progress has been made as the Cylinder head has been away for machining (skimming, valve seats, valve guides and pressure testing) and new valves have been installed. All the works to the head were carried out by W S Diesel Ltd, who also honed the block for me

|

| Block stripped and ready for cleaning |

|

| The block being "Honed" |

The gear box and transfer box were sent to Ashcroft Transmissions where in addition to the standard rebuild, the R380 gearbox had upgraded rear support bearings installed, a new HD pump and a new input shaft - http://www.ashcroft-transmissions.co.uk/manual-gearboxes.html

The LT230 Transfer box was fitted with a sleeved casing, an automatic torque biasing centre differential, new flanges and new bearings. - http://www.ashcroft-transmissions.co.uk/transfer-boxes.html

Why change the standard Land Rover differential for Ashcroft's automatic torque biasing centre differential to the transfer box? Rather than explain it myself I have taken the liberty of using Ashcroft's own words:-

"A little background on the LT230 centre diff. The centre diff is there to allow the props to turn at different speeds when cornering to stop drive train wind up. The speed difference is quite small and the centre diff gears are only designed to cope with these low speeds. If you are Off Road on snow or ice and you get wheel spin from one front wheel, what will happen is the rear prop will not be moving, the front will thus be going double speed, this means the small centre diff gears will be spinning like fury and after a matter of only a few seconds the planet gears will friction weld to the cross pins and the gears will fail etc. Of course in this situation the centre diff should be locked to avoid failure.

There are instances when it's not convenient to keep the diff locked or to constantly lock and unlock the diff as the available traction dictates, i.e, when racing fast on a low traction surface, the vehicle will not handle well when locked but is likely to wheel spin when unlocked.

Another example of where the ATB would help would be when rapidly changing from high to low traction surfaces, i.e. when driving on snow or ice,

In both of these examples the ATB will limit the amount the difference in prop shaft speed and transfer torque to the axle with traction.

The two big advantages are increased traction when unlocked and eliminating the weakness of the stock unlocked centre diff.

Note the ATB centre can still be locked like the stock unit when required, locking the diff is still advised when prolonged wheel spin is anticipated."

|

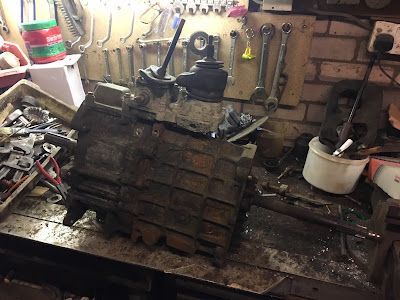

| The gearbox as removed |

|

| Stripping the gear linkage etc ready for shipping to Ashcroft |

|

| The amount of ferrous material on the sump plug magnet was a bit worrying |

|

| Gearbox and Transfer Box ready for collection |

|

| Gear Box and Transfer Box arrive back - nice and clean! |

My other large investment was in the turbo!

As I am undertaking a complete rebuild of the engine it is a good opportunity to improve on what was turned out from the factory. On a good day the 300 tdi lump will produce 122 Bhp (ex factory) which will drop with age and mileage. On a bad day (and it appears there were many of these!) the engine may only have had circa 112 Bhp when it left the factory.

The easiest way to get more power from the engine is to increase the size of the Inter cooler, a modification that more efficiently cools that air between the turbo charger and the engine. This in turn allows the injector pump to be reset to provide more fuel as cold air can carry more fuel than hot air.

Taking this a step further by increasing the size of the actual turbo, installing an even larger inter cooler and resetting the pump, the original 122 Bhp can be increase to circa 156 Bhp, not exactly an earth shattering figure but a reasonable increase.

More importantly from my point of view given that I am building an overland vehicle which will be on of the heavier Land Rovers out there the engine's torque should be increased from 195 ft.lb to 262 lb.ft making it more suited to hauling the heavier camper body up hills and across rough terrain.

Having looked into the tuning options that are available I opted for The Stage 3 kit from Allard Turbo Sport.

Allard are recognised as one of the leaders in the field of improving the performance of the basic Land Rover through turbo charging and have supercharged and turbocharged many Land Rover models, both petrol and diesel engined, going back as far as 1959 more than 20 years before the Land Rover factory introduced turbocharged engines!

The Basic Stage 3 Kit includes :-

- A full width high performance air to air all aluminium inter cooler, together with fitting kit comprising: mounting brackets, silicone hoses & clips,

- EGR replacement kit and aluminium pipes when required.

- A special build higher performance Garrett turbocharger which is supplied supplied complete with actuator, gaskets .

Given that the 300 tdi engine can be prone to overheating I was concerned that mounting a large inter cooler in front of the radiator would if anything make the engine run hotter, I opted to replace the standard radiator with a larger one which is both wider (the width is increased as the inter cooler that takes up part of the available space on the standard radiator will no longer be present) and deeper.

The radiator is also being supplied by Allard and although part of my original order has still to be delivered.

|

| The first parcel from Allard Turbo Sport |

|

| Rebuilt Turbo and new Inter cooler |

|

| Painting the Block |

Before starting the engine rebuild I spent a day tidying and cleaning my workshop as chaos had descended to it over the last 6 months and I wanted a clean and tidy environment in which to lay parts out and start the assembly. I also took this opportunity to fit a couple of LED spotlights above the work area to supplement the fluorescent tubes that provide back ground lighting.

|

| Pistons ready for cleaning |

|

| Top marking on the pistons |

|

| Lucas Assembly Lube |

I am using Lucas Assembly Lube during the re build as it will probably be a few months between the engine being put together and it actually being run

|

| Refitting the crankshaft |

|

| New bearing shells covered in Assembly Lube |

No comments:

Post a Comment

Note: only a member of this blog may post a comment.